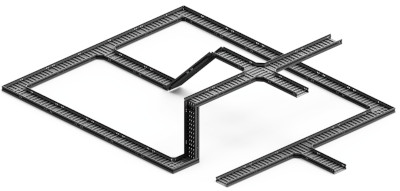

Cable Tray

Cable Management System

Cable Tray is available in variation based on the environmental and weather conditions for which it is used. Either 300 or 600 Volt with THHN, XLPE and EPR insulations are available, each with unique advantages and usages. From an expense standpoint, 600 volt Cable Tray carries a higher cost than the 300 volt due to the higher energy level. With the different types of insulations, EPR insulation carries a higher expensive due to its nature and what more it offers over THHN and XLPE cables.

Feature

- Easy and fast installation, Fast heat dispersion

- Easy for line check and cleaning

- Easy maintained and update

Applications

- Oil Industry , Electric Power , Lght Industry

- Telecommunications etc. professional cable routing systems

Material

- Carbon steel (Q235B)

- Stainless Steel ( 304L / 316L )

- Pre Galvanized Steel Plate

Surface treatment

- Hot Dip Galvanized(Standard According to BS EN 1461-1999)

- Electro Zinc(Standard According to BS EN 12329-2000)

- Powder Coated(Standard According to JG/T3045-1998,60)

Perforated Cable Tray

Perforated cable tray also called ventilated cable tray, It's offers good ventilation to the cable tray which will accordingly increase the current carring capacity of the cables.

Materials :

- Carbon Steel

- Pre Galvanized Steel Plate (GI, G.I.)

- Stainless Steel SS304 and SS316L

- Aluminum

- FRP (GRP, Fiberglass)

Specification:

- Thickness: 0.5 mm - 2.0 mm (22 - 27 Gauge)

- Height: 25 mm - 500 mm (Light, Medium, Heavy Duty)

- Width: 50 mm - 1200 mm

- Length: 2-10M (can be produced according to appointed length)

- Finished: Pre-galvanized (Z80 - Z275), hot dipped galvanized, power coating

Features:

- Increase the current carrying capacity of cables

- Takes up to 25 percent less space than ladder

- Hole pattern designed to provide maximum flexibility for positioning cable ties

- Fast speed of installation

Ladder Cable Tray

- Solid side rail protection and system strength with smooth radius fittings and a wide selection of materials and finishes.

- maximum strength for long span applications

- standard widths of 6,12,18, 24, 30, and 36 inches

- standard depths of 3, 4, 5, and 6 inches

- standard lengths of 10, 12, 20 and 24 feet

- rung spacing of 6, 9, 12, and 18 inches

- Ladder cable tray is generally used in applications with intermediate to long support spans, 12 feet to 30 feet.

Single Rail Cable Tray

- These aluminum systems are the fastest systems to install and provide the maximum freedom fort cable to enter and exit the system.

- Single hung or wall mounted systems in single or multiple tiers.

- Standard widths are 6, 9, 12, 18, and 24 inches.

- Standard depths are 3, 4, and 6 inches.

- Standard lengths are 10 and 12 feet.

- Single Rail Cable Tray is generally used for low voltage and power cables installations where maximum cable freedom, side fill, and speed to install are factors.

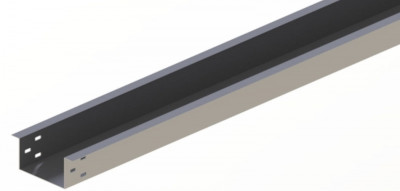

Channel Cable Tray

an economical support for cable drops and branch cable runs from the backbone

- standard widths of 3, 4, and 6 inches in metal systems and up to 8 inches in nonmetallic systems.

- standard depths of 1¼-1¾ inches in metal systems and 1, 1 1/8, 1 5/" and 2 3/16 inches in nonmetallic systems

- standard length of 10, 12, 20 and 24 feet

- Channel cable tray is used for installations with limited numbers of Cable Tray when conduit is undesirable. Support frequency with short to medium support spans of 5 to 10 feet.

Trough Cable Tray

- Moderate ventilation with added cable support frequency and with the bottom configuration providing cable support every 4 inches. Available in metal and nonmetallic materials.

- standard widths of 6, 12, 18, 24, 30, 36 inches

- standard depths of 3, 4, 5, and 6 inches

- standard lengths of 10, 12, 20 and 24 feet

- fixed rung spacing of 4 inch on center

- Trough cable tray is generally used for moderate heat generating applications with short to intermediate support spans of 5 feet to 12 feet.

Solid Bottom Cable Tray

- Nonventilated continuous support for delicate cables with added cable protection available in metallic and fiberglass.

- Solid bottom metallic with solid metal covers for nonplenum rated cable in environmental air areas

- standard widths of 6, 12, 18, 24, 30, and 36 inches

- standard depths of 3, 4, 5, and 6 inches

- standard lengths of 10, 12, 20 and 24 feet

- Solid Bottom cable tray is generally used for minimal heat generating electrical or telecommunication applications with short to intermediate support spans of 5 feet to 12 feet.

Wire Mesh Cable Tray